Swapped Out.

Where to begin… ok well Somewhere in the middle of July I removed my King Off-Road shocks in order to get them serviced:

…and while I was under there I ended up also removing the Total Chaos UCAs and temporarily installing my OEM stock UCAs and shocks:

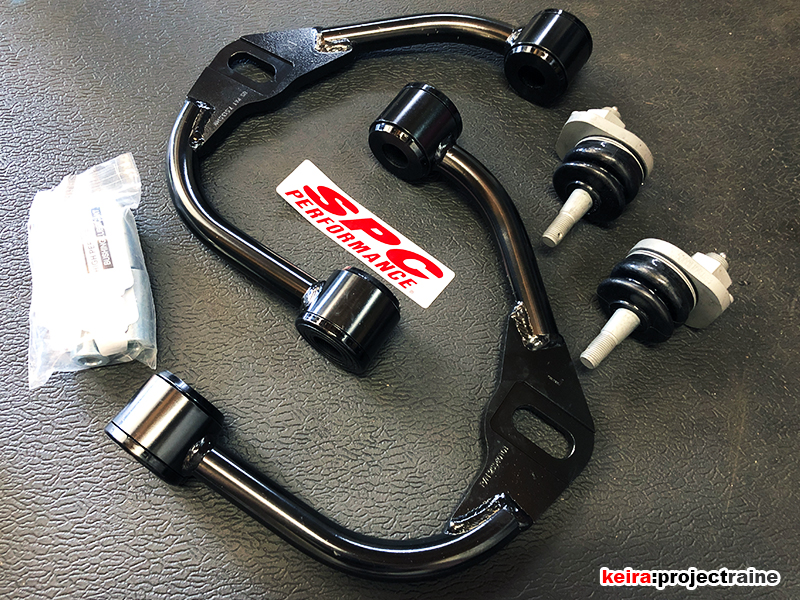

..and then within 3 days, this arrived in the mail:

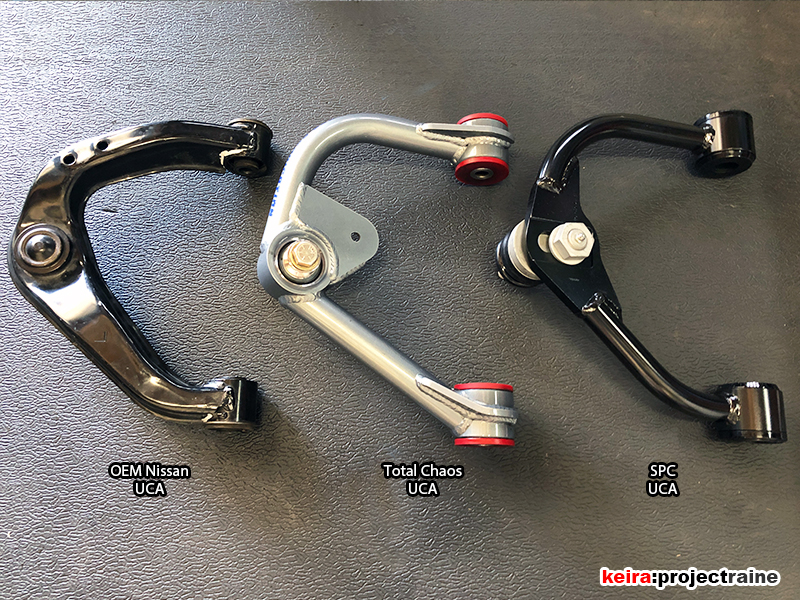

So I had a fresh new pair of SPC Adjustable Upper Control Arms (UCAs) ready to go, and after a couple more days my Kings arrived freshly serviced. Obviously both would be installed at the same time. Here’s a couple pics for reference first:

Okay – so I decided to go with SPC this time around because:

- Like the TC UCAs, the SPCs use comfortable, quiet urethane bushings on the main pivots;

- Also like the TC UCAs, they are a direct bolt-in on the chassis side;

- I like the accessible adjustability of caster and camber on the outboard side.

Was there anything wrong with the TC UCAs? Not at all. The only thing I could think of was that getting the TC UCAs aligned was a fine process due to the fact that all the alignment adjustments were still 100% done with the LCA camber bolts only. The install began as any other UCA/coilover install would go:

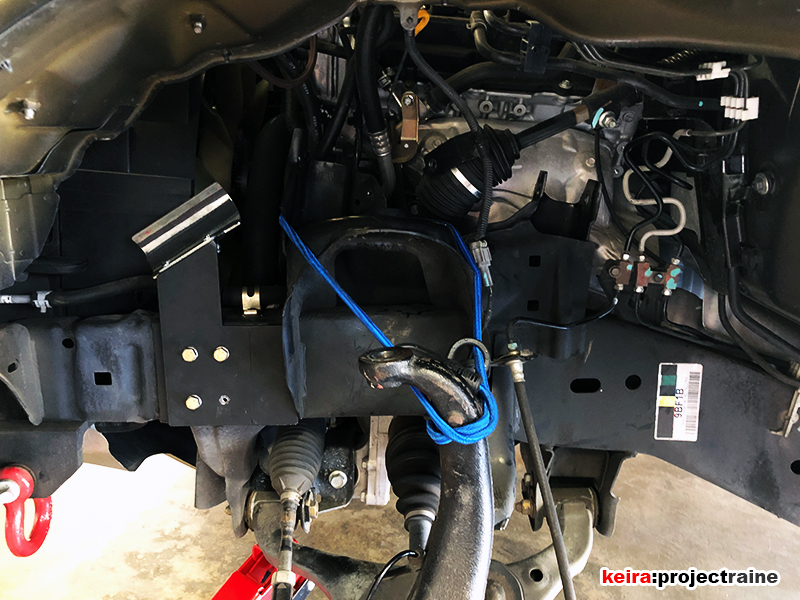

…except I now had to do the coil bucket mod in order to be able to use the SPC’s adjustable ball joints as intended. There’s other threads covering this mod, but basically the modification involves grinding away part of the coil bucket lip (that does not affect the integrity of the coil bucket) for clearance. There were no special tools needed for this – all I needed was a $19 Ryobi 5.5-amp angle grinder from Home Depot (grinding wheel included!). First I installed the SPC UCAs on the inboard side (to the chassis):

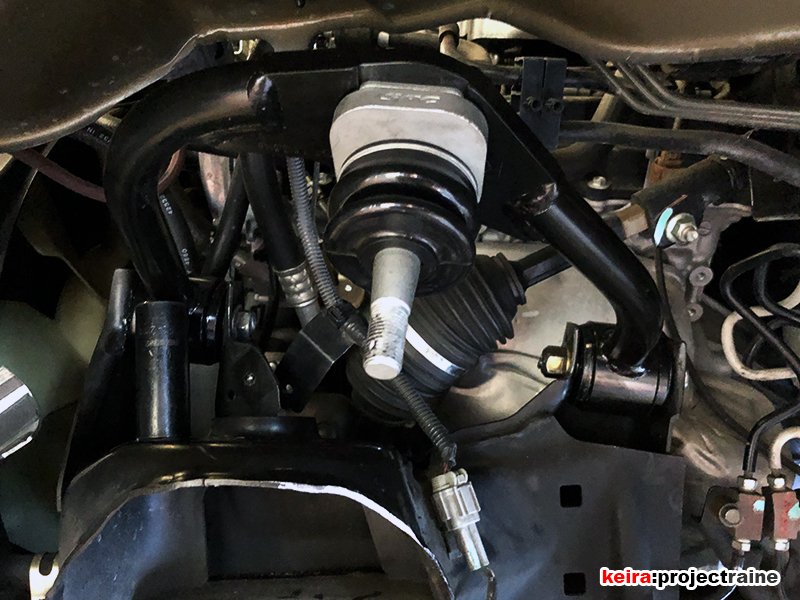

Next I moved the outer ball joint to the inner-most position (most camber). This was my guide; from here I would drop the UCA until there was contact with the coil bucket lip, mark where the contact is with a Sharpie marker, then grind away slowly, checking clearance every minute or so. After about 20 careful minutes (doing the other side was much faster once I knew how the process went) of grinding a little, checking clearance, then grinding some more, I had enough material removed from the coil bucket lip to clear the SPC’s ball joints:

The last step to the mod was to protect the grinder area with a paint marker to prevent any chance of rust forming:

Once this was dry, I re-installed my King coilovers, attached the SPC UCA’s to the spindle, and it was off to get an alignment the next afternoon.

After the alignment, my truck tracked straight and true. There was no noise from the new SPC UCAs, and because of the added adjustability (compared to the Total Chaos UCAs) my alignment tech easily got the front wheels aligned to what I like to call “exact spec” – in other words, when I get an alignment done, I prefer all the numbers to match from left to right.

Fun Fact: Regular alignment shops will make adjustments until the numbers fall within an acceptable window, which can mean the your alignment will be “within spec” but the left camber and right camber might be two different actual angles.

So for me, “exact spec” is a custom alignment where caster, camber, and toe are matching exactly from left to right… so if the left wheel has 1.00 degree of negative camber, the right wheel must also have exactly 1.00 degrees of negative camber. Likewise if the front right wheel has 2.55 degrees of caster, the front left is also adjusted to exactly 2.55 degrees of caster. Same with toe adjustment. Also, I make sure the tech does not compensate for road crown – this is when regular alignments have some built-in pull to the left, to compensate for how most roads are sloping to the right (for drainage) anyways. With zero road crown compensation, when I have my steering wheel straight, I know that the wheels are pointed exactly straight. Call it picky, but that’s how I am.